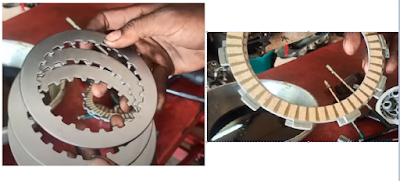

In all two wheelers, multi plate type clutch is used. Clutch is used to engage and disengage the power flow between the crankshaft and the transmission system. One end of the clutch assembly is connected to the crankshaft and other end is directly connected to the input shaft of the gearbox. We'll use clutch while upshifting or downshifting the gears. Normally, clutch will be in engaged position. When we activate the clutch lever, actually we are disengaging the clutch. Universally, multi plate clutch mechanism is used in all motorbikes as it consumes less space with high efficiency. Instead of using single plate, manufacturers designed and developed number of plates to transmit the power and torque as the single plate clutch do. Life of the clutch purely depends on our way of handling it. As we know, it does the important job of transmitting engine's power to wheels via gearbox. So in this post, we'll see some common problems in a motorbike's clutch system.

Clutch bell shake

In the clutch assembly, components like friction plate, pressure plate, clutch springs will be fixed in the component named clutch bell or clutch basket or clutch housing. The power from the crankshaft is transferred to this clutch bell first and then only the power transfers to the input shaft of the gearbox via clutch plates. The bell assembly is riveted to the gear. Inside that, a crush rubber will be present for smooth engagement by absorbing jerks. Normally, gear and the housing will be a single unit. If that rubber is damaged, housing and gear moves independently. If you tend to ride continuously at this condition, your shifts will not be smooth and you'll feel jerks while popping the cutch lever. This'll also create unwanted noise because of the shake.

If you visit showroom regarding this problem, they'll replace the entire clutch assembly which is not necessary. If possible, visit local mechanic shop and dismantle the whole clutch assembly. Take the clutch housing to the nearest lathe shop. They'll remove the rivets and separate the gear and bell. After that, you can install new crush rubbers and finish the process by installing new rivets. Thus the problem is rectified and you can start to assemble the clutch.

Slipping of clutch

You can able to figure out this problem by twisting the throttle high and not getting enough power from the engine to the wheel. Normally when the clutch is in engaged position, friction and steel plates will be in contact thus making way for power transmission. But in this case, the friction between those two plates will be faded away. First thing you have to check is the clutch cable adjustment. If the wire is overstretched, then there'll be poor engagement of clutch. If the wire is under stretched, there'll be poor disengagement of clutch. This clutch cable's quality and tension plays an important role in maintaining the friction between the plates. So it is recommended to adjust the clutch cable's tension or replace it if necessary. After that, check whether the free play of the lever is kept correctly. If you tend to ride continuously without looking after this problem, there's no doubt that the plates will worn out quickly. Clutch springs are responsible for engaging the clutch plates to come back to original position after disengaging. Clutch springs tends to loose stiffness after long usage. If you are facing this problem, make sure that the clutch springs are in good condition.

Judder

If you feel sudden forward jerk most often after popping the clutch, then it is known as clutch judder. Unsmooth engagement with more vibrations cause the motorbike to jerk. This may confuse you. If the crush rubber in the basket is damaged, you'll experience similar kind of problem. This problem not happens because of worn out clutch plates. This problem is the result of various factors such as misalignment between clutch plates, between shafts and bearings, between spring seats and housing, locks and pressure plates. Clutch bolts should be tightened in the correct manner that is in opposite directions. Tightening it in the opposite direction will lead you to correct seating and alignment.

Drag

In this case, friction between the clutch and friction plate increases. You can able to figure out this problem by finding difficulty in disengaging the clutch. Damaged clutch plates cause this kind of problem. In some cases, due to high heat, the friction surface will be melted and sticks to the steel plate. Friction between the clutch plates increases due to lack of lubrication. Lubrication between the plates helps to cool it down and reduce the friction. To get rid of this problem, check whether there's sufficient amount of motor oil is present and check the alignment of the clutch plates. One side of the plate will be flat and other side will be tapered. Install it according to the manufacturer's spec. If the plates are damaged, replace it with the new set.

Clutch bell shake

In the clutch assembly, components like friction plate, pressure plate, clutch springs will be fixed in the component named clutch bell or clutch basket or clutch housing. The power from the crankshaft is transferred to this clutch bell first and then only the power transfers to the input shaft of the gearbox via clutch plates. The bell assembly is riveted to the gear. Inside that, a crush rubber will be present for smooth engagement by absorbing jerks. Normally, gear and the housing will be a single unit. If that rubber is damaged, housing and gear moves independently. If you tend to ride continuously at this condition, your shifts will not be smooth and you'll feel jerks while popping the cutch lever. This'll also create unwanted noise because of the shake.

If you visit showroom regarding this problem, they'll replace the entire clutch assembly which is not necessary. If possible, visit local mechanic shop and dismantle the whole clutch assembly. Take the clutch housing to the nearest lathe shop. They'll remove the rivets and separate the gear and bell. After that, you can install new crush rubbers and finish the process by installing new rivets. Thus the problem is rectified and you can start to assemble the clutch.

Slipping of clutch

You can able to figure out this problem by twisting the throttle high and not getting enough power from the engine to the wheel. Normally when the clutch is in engaged position, friction and steel plates will be in contact thus making way for power transmission. But in this case, the friction between those two plates will be faded away. First thing you have to check is the clutch cable adjustment. If the wire is overstretched, then there'll be poor engagement of clutch. If the wire is under stretched, there'll be poor disengagement of clutch. This clutch cable's quality and tension plays an important role in maintaining the friction between the plates. So it is recommended to adjust the clutch cable's tension or replace it if necessary. After that, check whether the free play of the lever is kept correctly. If you tend to ride continuously without looking after this problem, there's no doubt that the plates will worn out quickly. Clutch springs are responsible for engaging the clutch plates to come back to original position after disengaging. Clutch springs tends to loose stiffness after long usage. If you are facing this problem, make sure that the clutch springs are in good condition.

If you feel sudden forward jerk most often after popping the clutch, then it is known as clutch judder. Unsmooth engagement with more vibrations cause the motorbike to jerk. This may confuse you. If the crush rubber in the basket is damaged, you'll experience similar kind of problem. This problem not happens because of worn out clutch plates. This problem is the result of various factors such as misalignment between clutch plates, between shafts and bearings, between spring seats and housing, locks and pressure plates. Clutch bolts should be tightened in the correct manner that is in opposite directions. Tightening it in the opposite direction will lead you to correct seating and alignment.

Drag

In this case, friction between the clutch and friction plate increases. You can able to figure out this problem by finding difficulty in disengaging the clutch. Damaged clutch plates cause this kind of problem. In some cases, due to high heat, the friction surface will be melted and sticks to the steel plate. Friction between the clutch plates increases due to lack of lubrication. Lubrication between the plates helps to cool it down and reduce the friction. To get rid of this problem, check whether there's sufficient amount of motor oil is present and check the alignment of the clutch plates. One side of the plate will be flat and other side will be tapered. Install it according to the manufacturer's spec. If the plates are damaged, replace it with the new set.